Bachus GeoSyntec Consultants 5950 Live Oak Parkway Suite 330 Norcross Georgia 30093 USA ABSTRACT This paper provides the practicing designer with a comprehensive systematic approach to solving common filtration design problems. Geotextile Strength Requirements for Drains.

Water Free Full Text Changes Of Permeability Of Nonwoven Geotextiles Due To Clogging And Cyclic Water Flow In Laboratory Conditions Html

GUIDE FOR THE USE OF GEOTEXTILES.

. The main aim in both cases is to allow the passage of water from the covered layer. The benefits of using geotextiles in pavements and other transportation applications have triggered a proliferation of products. Design Guide Fibertex Geotextiles.

Minimum Geotextile Strength Properties for Survivability FHWA 1989. 2-5 3-1 3-4. Designing with geotextiles for filtration is essentially the same as designing graded granular filters.

First you are going to need to calculate an estimate of. Geotextile fabric shall be a Mirafi 160N or equivalent. To distribute Design Note DN No.

Recommended Geotextile Property Requirements for Railroad Applications. Geotextile Filter Design Criteria. The goal of this application is to remove water while preventing soil and or any other fine particles from passing through.

The goal of Whole Building Design is to create a successful high-performance building by applying an integrated design and team approach to the project during the planning and programming phases. For coarse-sands silts and clays it is recommended to use SKAPS nonwoven geotextiles. The drylaid needlepunch technology is based on a two step process.

Can you point me in the right direction. A geotextile is similar to a soil in that it has voids pores and particles filaments and fibers. Filter Design Retention Criteria contd AOS or O95 B D85 For dynamic pulsating or.

Physical properties of the geotextile. Material specifications should conform to OPSS 1860 for Class II geotextile fabrics. However detailed design information can be obtained by contacting any TenCate Geosynthetics Europe regional office.

The formation of biofilm on geotextiles has also been shown to improve water quality. By degrading petroleum hydrocarbons. Geotextile filter design guide TABLE 2 Typical Hydraulic Gradients Drainage application Typical hydraulic gradient 10 1-5 1 1-5 1-5 1-5 2 3 to 10 h 0 h 29 Standard dewatering trench Vertical wall drain Pavement edge drain Landfill leachate collectiondetection removal system Landfill leachate collection removal system Landfill closure surface water.

All I have from the site is a grain size analysis of the sandy subgrade soil. The following step-by-step geotextile design methodology DESIGN APPROACH SYSTEMATIC The proposed design methodology represents years of research and experi-ence in geotextile filtration design. Note when expansive clays are.

Geotextiles as Filters Keywords. The level of design required. Consult with your Authorized Helix Retailer or an Authorized Helix Contractor who.

In 1998 for TC Mirafi. Geotextiles as Filters Author. 24 Guide for the Use of Geotextiles.

For fine-grained sands it is recommended to use SKAPS Woven Monofilament products. WBDG is a gateway to up-to-date information on integrated whole building design techniques and technologies. O Kg 100ks 90 Mediuml 011 ight b O Kg 100ks 90 b Heavy 010 O Kg 100ks.

Define the Application Filter Requirements Step 2. Geotextile Filter Design Criteria. Geotextiles one among the different geosynthetic products can be used for a number of functions or applications in pavement design.

Recommended Geotextile Minimum Strength Requirements. The geotextile percent open area shall be 4 - 6 for woven geotextiles and the porosity shall be at least 30. Filter Design Retention Criteria contd AOS or O95 B D85 Silts or Clays 50 passing No.

When installing geotextiles an overlap of 150 - 300 mm should be used. Filter fabric separates ballast stone from the insulation on a protected membrane roof Left side of picture. The geotextile shall have an Apparent Opening Size that is less than 021 mm.

By reducing organic pollutant and nutrient concentrations. Pin Spacing Requirements in Erosion Control Applications. Geotextiles are becoming widely used in the design and construction of soil and water conservation practices and structures.

The schematics in the following pages do not encompass all of the possibilities and pond design configurations. After a detailed study of research carried out here and in Europe on both conventional and geotextile filters developed a widely used design procedure for geotextile filters for drainage and permanent erosion-control applications. However because of the shape and arrangement of the filaments and the compressibility of the structure with geotextiles the geometric relationships between filaments and voids is.

Recommended Geotextile Minimum Strength Requirements. While this abundance of new products has led to reduction in costs it has also made it. Place the selected rip-rap geotextile without wrinkles or folds.

The geotextile shall have a minimum permeability of 84 x 10-3 cms. Kaytech geotextiles as filters nonwovens and wovens geotextile flters granular filters composite filters Created Date. They can be effective in improving drainage.

Luettich SM Giroud JP Bachus RC. Here you can see filter fabric being used to protect the EPDM membrane from. About Geofilter Geofilter was developed by Flexwave International Inc.

Geotextile Type B woven 1 nonwoven 18 For both AOS 3mm. Through the International Trading Division. Recommended Geotextile Property Requirements for Railroad Applications.

The approach presents a logical progression through seven steps. CONSTRUCTION 2 Fibertex Geotextiles Fibertex Geotextiles - are needlepunched nonwoven fabrics made from polypropylene. Geotextile Strength Requirements for Drains.

This is achieved in combination with a filter behind the geotextile. The Helix Design Guide should be used as a reference to help determine which pond meets your goals and expectations. I am doing a geotextile filter design for a highway edge drain.

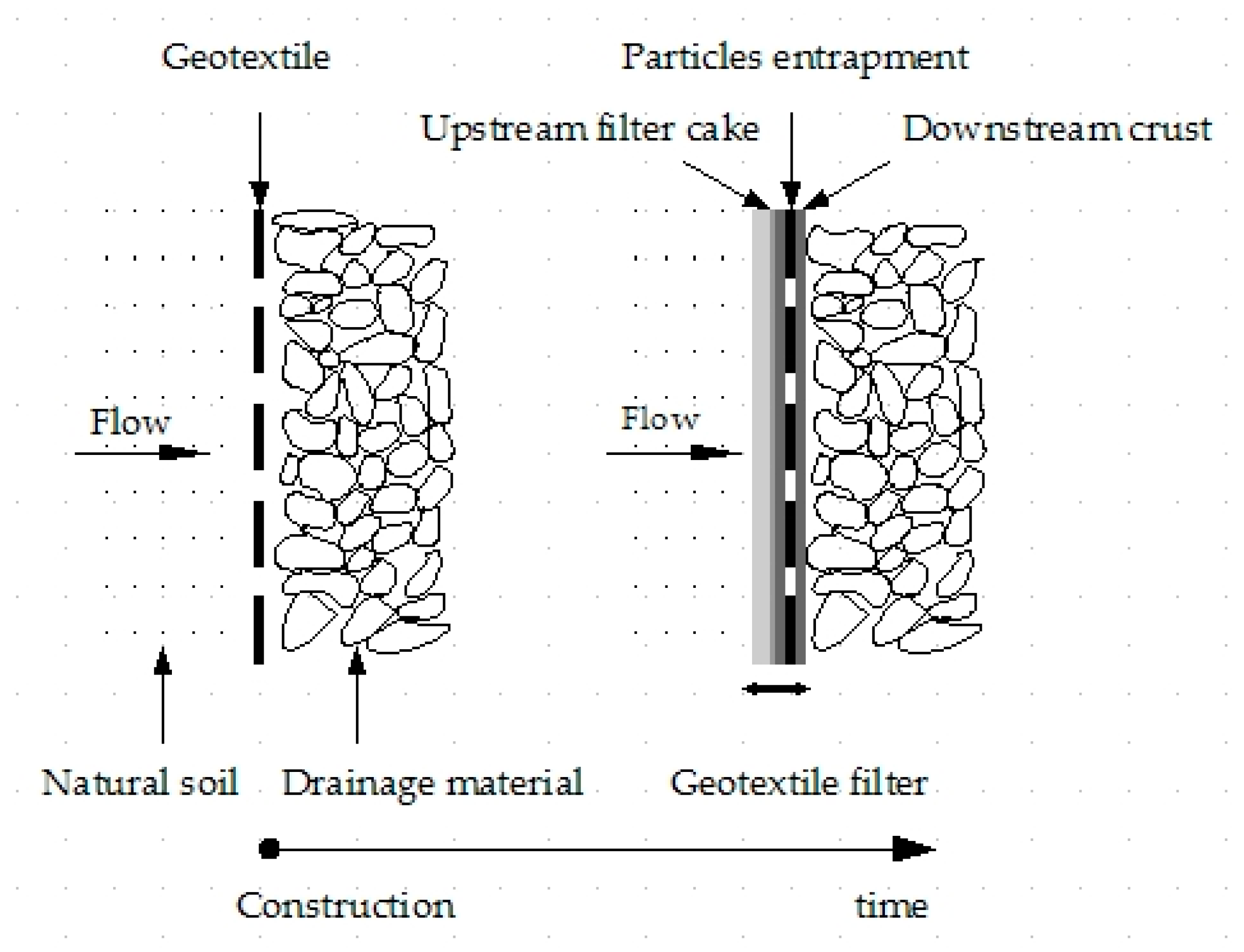

1992 Geotextile Filter Design Guide Geotextiles and Geomembranes v11 p355-370. Geotextiles you can design on Filtration Schematic diagram showing geotextile filters Nonwoven continuous filament needlepunched Since 1978 a range of nonwoven continuous filament needlepunched geotextiles has been manufactured by Kaytech at Atlantis South Africa and distributed throughout Southern Africa. Geotextiles and Geomembranes 11 1992 355-370 Geotextile Filter Design Guide S.

For information about Geofilter contact TC Mirafi at 1 800-234-0484 or 1 706-693-2226 and ask for technical assistance regarding geotextile filter. Pin Spacing Requirements in Erosion Control Applications. Using geotextile infiltration is similar to using in stabilization.

Geotextiles Filter Fabric and Roofing. The design analysis to determine the required tensile strength in the geotextile for high embankment construction is not contained in this design manual. Firstly polypropylene resin is extruded into fibres.

Design Guide Fibertex Geotextiles Fibertex Nonwovens Pdf Catalogs Technical Documentation Brochure

The Ultimate Guide To Geotextiles Mainline Materials

Geotextile In Filtration And Drainage Applications A Earth Dam B Download Scientific Diagram

Geotextile Installation Guide In Road Stabilization Zarifindustrial

Geotextile An Overview Sciencedirect Topics

Geotextile Installation Guide In Road Stabilization Zarifindustrial

0 comments

Post a Comment